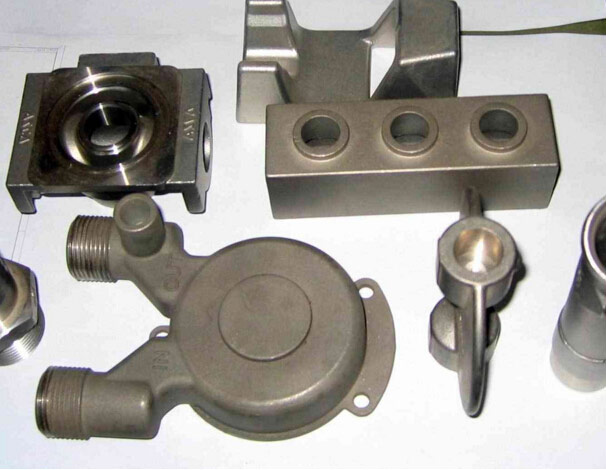

Problems and Countermeasures of domestic precision casting products

时间:2022/01/11查看:743

According to the analysis of insiders, there are three major problems in China's precision casting products. The environmental problems of China's foundry industry are also reflected in the excessive consumption of natural resources. The above shows the severity of environmental problems in China's precision casting industry. Adopting high technology to realize green casting is the key problem to be solved at present.

1、 The process level is low and the quality of precision casting products is poor

Casting cracks are serious.

The segregation and inclusion defects of large castings are serious. After solidification of large steel castings and ingots, there are problems of macro segregation and coarse grain in the riser root and thick section of castings.

The application of simulation software is not popular. Casting process simulation is a necessary link in casting production. In foreign countries, if there is no computer simulation technology, there will be no order. The computer simulation of China's foundry industry started early. Although the development ability of the core computing part is strong, the overall software packaging ability is poor, resulting in the mature commercial software development far behind the developed countries. A considerable number of foundry enterprises are deterred from the computer simulation technology and lack of trust. At present, although this situation has improved, few enterprises that have purchased casting simulation software can play its role, and there is an urgent need for software application training for enterprise employees.

The production capacity of ordinary castings is surplus, and the manufacturing of high-precision castings is still difficult.

Large machining allowance of precision casting. Due to the lack of scientific design guidance, it is difficult for process designers to control deformation based on experience, and the machining allowance of casting is generally 1-3 times larger than that in foreign countries. Large machining allowance, serious energy consumption and raw material consumption of castings, long machining cycle and low production efficiency have become the bottleneck restricting the development of the industry.

The design of gating system is unreasonable. Due to improper design, there are air entrainment, inclusions and other defects, resulting in low yield and qualified rate of castings.

2、 Serious environmental pollution and poor working environment

Except for a few large-scale enterprises in China, such as FAW, FAW, heavy lifting and Shenyang Liming company, which have sophisticated production equipment, advanced precision casting technology and basically in place environmental protection measures, most foundry sites have outdated production equipment and backward technology, and generally pay little attention to environmental protection.

In the 1980s, the government made professional adjustments to enterprises with small scale, low technical level and serious pollution, which improved the intensive degree of enterprises, but the extensive characteristics of casting production have not been fundamentally changed.

The environmental problems of China's foundry industry are also reflected in the excessive consumption of natural resources.